LNG Arzew Sonatrach

Gas Processing

LNG Arzew Saipem Chyoda jv for Sonatrach Project (Algeria, 2013 and 2014)

The Arzew new LNG liquefaction train or GL3-Z project started in july 2008 by Sonatrach is situated about 400km (249 miles) west of Algiers. The onshore contract was worth €2.8bn and involved the construction of a new LNG liquefaction train on a brownfield site in the industrial zone of Arzew adjacent to the existing refinery.

Sonatrach awarded Saipem, in a joint venture with Chiyoda, the lump sum turn key contract for the new Arzew LNG Train (GL3-Z) project. The contract encompassed the EPC (engineering, procurement and construction) of a single-train gas liquefaction (LNG) plant, with a capacity of 4.7 million tonnes of LNG per annum. We supplied to Saipem Venturi Tubes, Orifices Plates, Thermocouples and Thermowells for the single-train gas liquefaction plant. That time Saipem was named for the first time as the main contractor of a large gas liquefaction (LNG) plant, asserting its reputation as an integrated player, capable of managing large and complex turnkey projects in the high tech market of the LNG sector.

The EPC contract was awarded to a joint venture of Saipem/Snamprogetti and Chiyoda on a turn-key basis for a 4.7-million-ton-a-year liquefaction train and associated infrastructure. This was the first time that Saipem has been the main contractor for a large LNG project. Sonatrach at that time already had an oil refinery at Arzew, which carries out topping and reforming, and has a capacity of 60,000bpd.

Opened in 1973, the refinery processes crude piped to it along the Haoud El Hamra / Arzew pipeline. Half of the output is for domestic consumption and half for export. Alongside the refinery are two gas liquefaction plants – the GL1-Z and GL2-Z – which have recently undergone refurbishment of equipment and de-bottlenecking by Bechtel and IHI and Itochu of Japan.

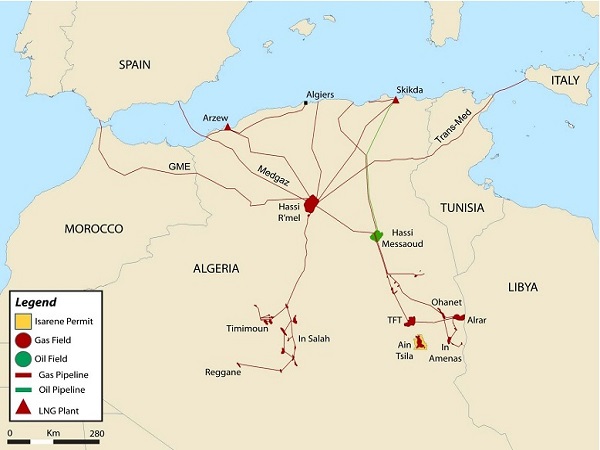

Algeria has proven natural gas reserves of 4.5 trillion cubic metres, which amounts to about 2.6% of the world total, and is the world's fourth-largest gas producer, supplying 25% of the EU's natural gas imports. Sonatrach runs the largest gas field, the Hassi R’Mel, which holds about half the country's gas reserves (2.4 trillion cubic feet). The problem is that Algeria needs more outlets for gas exports to capitalise on its natural resources, and LNG liquefaction terminals offer more scope for customers such as the US, Japan and Canada. Via two pipelines Algeria already exports gas to Italy and supplies 50% of Spain's gas.

English

English  Chinese

Chinese

Administrative Office - Piazza Duca d’Aosta, 12 - 20124 – Milano +39.02.72022835 +39.02.72023798 fax -

Administrative Office - Piazza Duca d’Aosta, 12 - 20124 – Milano +39.02.72022835 +39.02.72023798 fax -